Dedicated Integrated Combustion System for RTO/TO/VOCs

Category:

Equipment Center

Combustion Control System

Gas combustion system

Fuel Combustion System

Low-Nitrogen Combustion Control System

Related document download

Helpline:+8618123502747

Office phone:+860757-83370984

Keywords: diesel burner, light diesel burner

undefined

Product Details

• Non-standard products can have their parameter specifications adjusted according to customer needs,

For detailed pricing and other information, please contact Ms. He at 18123502747.

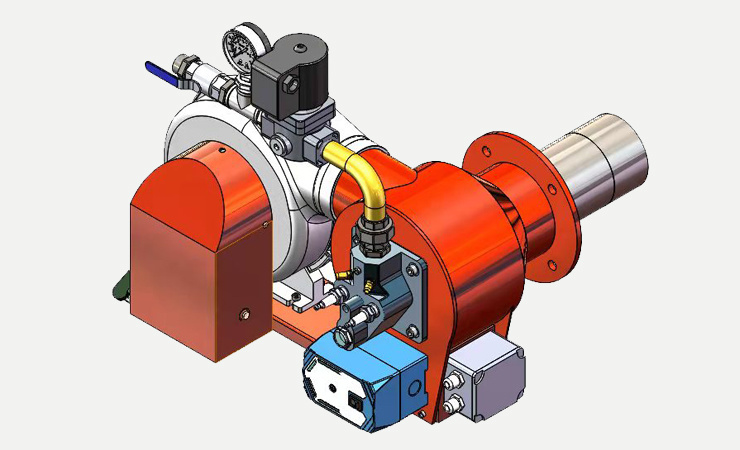

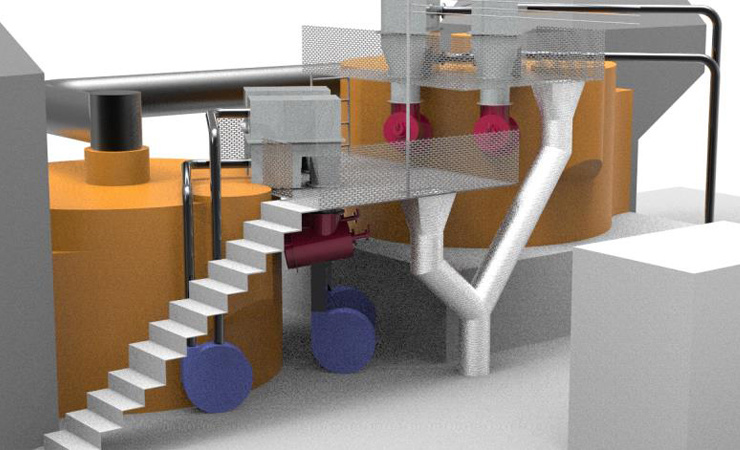

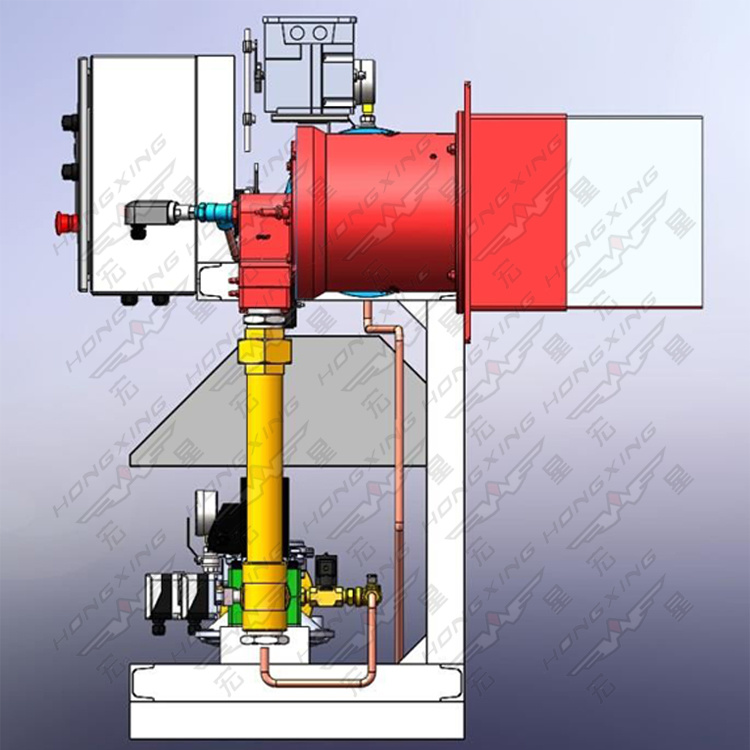

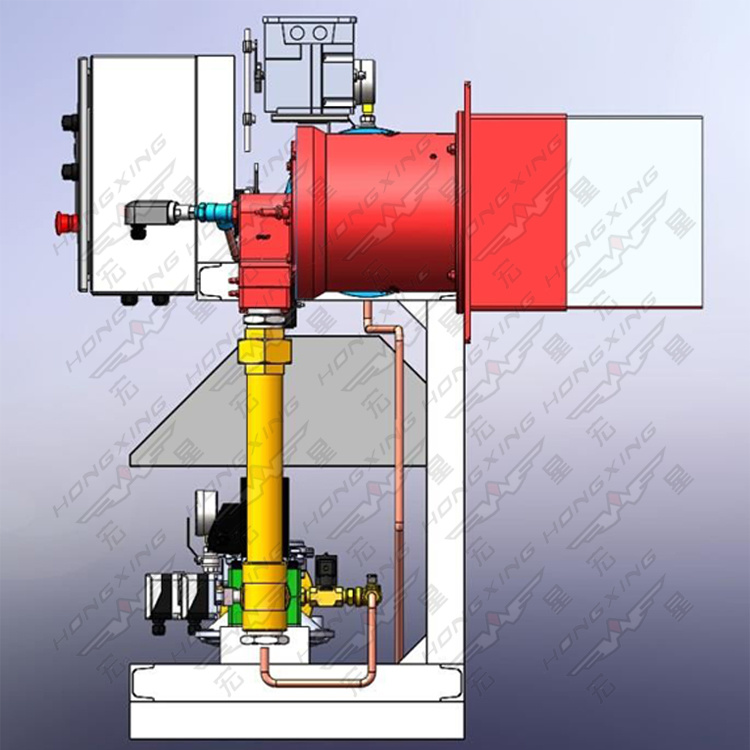

• Product Name: Integrated Combustion System—Specifically Designed for RTO/TO/VOCs Systems

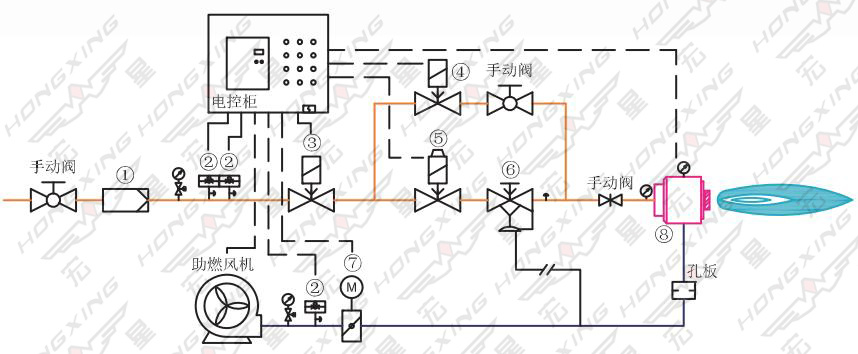

The HXPB combustion system is designed specifically for the characteristics of RTO/TO/VOCs applications in exhaust gas incineration treatment. It integrates burners, gas pipeline valves, air pipeline valves, and a combustion control cabinet.

The system has the following key advantages:

• Fuel media: natural gas, liquefied gas,

• Integrated system with a compact design, making on-site installation convenient;

• Pre-commissioning of the system reduces the workload for on-site services;

• High modulation ratio, up to 1:100, which helps maintain stable system temperature control;

• Maximum operating temperature of 1500°C, with a long service life;

• Safe and reliable, with system load meeting European and American design standards;

• Optional configurations to meet diverse usage environment requirements;

• Adaptable to various furnace back pressures, with a high ignition success rate;

• Low nitrogen oxide emissions, environmentally friendly;

Customizable—contact us for more details on product specifications.

You can contact Ms. He by phone!

| Model | Power KW |

Power 10,000 kcal/h |

Natural gas m³/h |

Natural gas pressure KPa |

Combustion air pressure Kpa |

Adjustment Ratio Min: Max |

HXPB-40 |

50 |

4.3 |

5 |

30 |

5 |

1:100 |

HXPB-50 |

90 |

7.8 |

9 |

30 |

5 |

1:100 |

HXPB-50A |

150 |

13 |

15 |

30 |

5 |

1:100 |

HXPB-50B |

220 |

20 |

23 |

30 |

5 |

1:100 |

HXPB-65A |

300 |

26 |

30 |

30 |

5 |

1:100 |

HXPB-80 |

450 |

40 |

47 |

30 |

5 |

1:100 |

HXPB-80A |

600 |

52 |

60 |

30 |

5 |

1:100 |

HXPB-100 |

1000 |

86 |

100 |

300 |

5 |

1:40 |

HXPB-150 |

1500 |

130 |

151 |

30 |

5 |

1:40 |

HXPB-200 |

2200 |

190 |

220 |

30 |

5 |

1:40 |

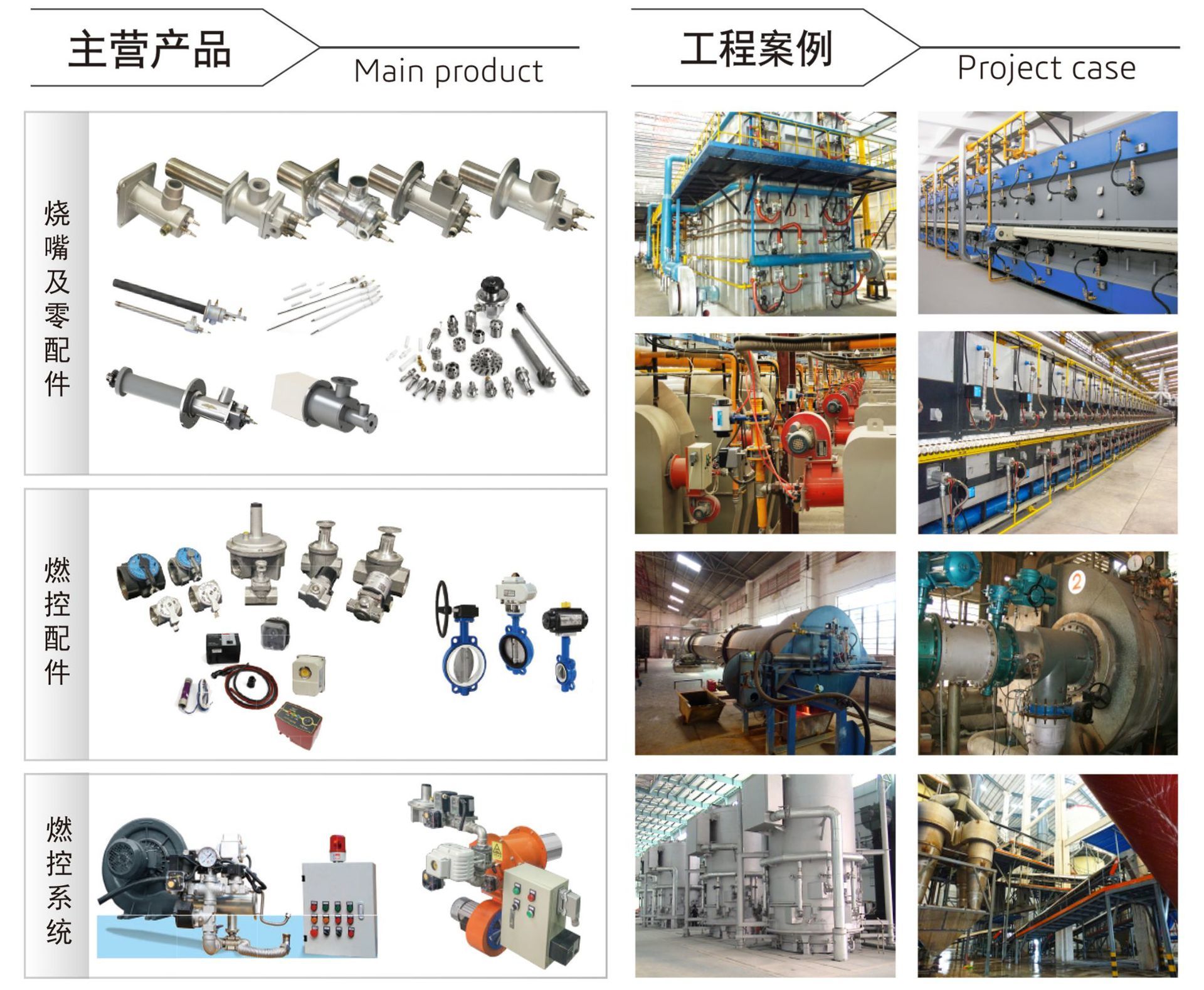

Foshan Hongxing Jieneng Technology Co., Ltd. (formerly Hongxing Thermal Energy Machinery Equipment Co.) is a high-tech company integrating production, education, and research, specializing in thermal energy combustion equipment, complete sets of automatic combustion control systems for kilns, eco-friendly flue gas treatment devices, metal heat-treatment equipment, and the design of agricultural food film, leather, and coating drying systems. Our company primarily manufactures combustion burners, controllers, actuator units for combustion control, combustion control valves, and hot-air furnace dryers, among other products. We boast a dedicated in-house technology development team, including several senior engineers and professionals holding advanced technical certifications. For years, we’ve been committed to addressing challenges in kiln combustion technology, delivering solutions that are not only more energy-efficient and stable than comparable products but also earning widespread praise and recognition from industry experts and leading kiln manufacturers alike.

Customer recognition fuels Hongxing's momentum.

Hongxing at the Exhibition Mechanical

: Can

: Can

• Contact: Ms. He

• Phone: 18123502747

• Address: 1st Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province Hongxing's power users endorse Hongxing's power.

Safety-Production Workshop

Product Description

• Non-standard products can have their parameter specifications adjusted according to customer needs,

For detailed pricing and other information, please contact Ms. He at 18123502747.

• Product Name: Integrated Combustion System—Specifically Designed for RTO/TO/VOCs Systems

The HXPB combustion system is designed specifically for the characteristics of RTO/TO/VOCs applications in exhaust gas incineration treatment. It integrates burners, gas pipeline valves, air pipeline valves, and a combustion control cabinet.

The system has the following key advantages:

• Fuel media: natural gas, liquefied gas,

• Integrated system with a compact design, making on-site installation convenient;

• Pre-commissioning of the system reduces the workload for on-site services;

• High modulation ratio, up to 1:100, which helps maintain stable system temperature control;

• Maximum operating temperature of 1500°C, with a long service life;

• Safe and reliable, with system load meeting European and American design standards;

• Optional configurations to meet diverse usage environment requirements;

• Adaptable to various furnace back pressures, with a high ignition success rate;

• Low nitrogen oxide emissions, environmentally friendly;

Customizable—contact us for more details on product specifications.

You can contact Ms. He by phone!

| Model | Power KW |

Power 10,000 kcal/h |

Natural gas m³/h |

Natural gas pressure KPa |

Combustion air pressure Kpa |

Adjustment Ratio Min: Max |

HXPB-40 |

50 |

4.3 |

5 |

30 |

5 |

1:100 |

HXPB-50 |

90 |

7.8 |

9 |

30 |

5 |

1:100 |

HXPB-50A |

150 |

13 |

15 |

30 |

5 |

1:100 |

HXPB-50B |

220 |

20 |

23 |

30 |

5 |

1:100 |

HXPB-65A |

300 |

26 |

30 |

30 |

5 |

1:100 |

HXPB-80 |

450 |

40 |

47 |

30 |

5 |

1:100 |

HXPB-80A |

600 |

52 |

60 |

30 |

5 |

1:100 |

HXPB-100 |

1000 |

86 |

100 |

300 |

5 |

1:40 |

HXPB-150 |

1500 |

130 |

151 |

30 |

5 |

1:40 |

HXPB-200 |

2200 |

190 |

220 |

30 |

5 |

1:40 |

Foshan Hongxing Jieneng Technology Co., Ltd. (formerly Hongxing Thermal Energy Machinery Equipment Co.) is a high-tech company integrating production, education, and research, specializing in thermal energy combustion equipment, complete sets of automatic combustion control systems for kilns, eco-friendly flue gas treatment devices, metal heat-treatment equipment, and the design of agricultural food film, leather, and coating drying systems. Our company primarily manufactures combustion burners, controllers, actuator units for combustion control, combustion control valves, and hot-air furnace dryers, among other products. We boast a dedicated in-house technology development team, including several senior engineers and professionals holding advanced technical certifications. For years, we’ve been committed to addressing challenges in kiln combustion technology, delivering solutions that are not only more energy-efficient and stable than comparable products but also earning widespread praise and recognition from industry experts and leading kiln manufacturers alike.

Customer recognition fuels Hongxing's momentum.

Hongxing at the Exhibition Mechanical

: Can

: Can

• Contact: Ms. He

• Phone: 18123502747

• Address: 1st Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province Hongxing's power users endorse Hongxing's power.

Recommended Products

Product Inquiry

* Note: Please ensure you provide accurate information and keep your contact details up to date. We will reach out to you as soon as possible.

Foshan Hongxing Jieneng Technology Co., Ltd.

Company Address: 1st Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province

Helpline:18123502747

Office phone:0757-83370984

Fax: 0757-85653501

E-mail:fshongxing.cn@163.com

Website: http://www.fshongxing.cn

You can also submit your information online, and we’ll get back to you within 24 hours!