Ceramic Industry Solution

Advantages of the Plan

Traditionally, domestic liquid-tank heating systems have relied on steam or high-temperature water for heat exchange during processes such as pre-cleaning, phosphating, and degreasing. This approach necessitates the installation of complex heating equipment, extensive piping networks, valves, and heat-exchange units both inside and outside the factory, around the liquid tanks. Not only does this consume valuable space within the facility, but it also drives up maintenance costs. Moreover, heat transfer efficiency tends to be low when using high-temperature water or steam, leading to higher operational expenses.

Fuelled by gases such as natural gas, propane, and butane, the flame burns directly within the heating tubes at the bottom of the liquid tank, efficiently and evenly heating the liquid inside through the optimized length and arrangement of the tubes. This system achieves a thermal efficiency of over 80% and enables automatic temperature control, making it the future direction and optimal choice for industrial liquid-tank heating applications.

Product Introduction

It can be applied to a variety of medium- and low-temperature heating applications, such as hot-air ovens, industrial drying furnaces, and hot-air stoves, and is particularly well-suited for scenarios where heating space is limited.

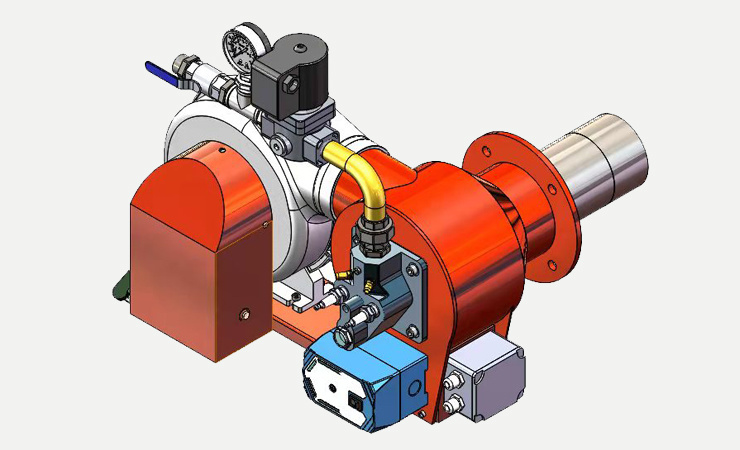

The Linofire-HC series burners are high-power direct-fired hot-air heaters designed in accordance with the EU gas industry safety standard EN746-2. Installed directly within air ducts, the Linofire-HC burners quickly generate a wide flame coverage area, making them ideal for various medium- and low-temperature heating applications—such as hot-air ovens, industrial drying furnaces, and hot-air stoves—especially suited for scenarios where space for heating is limited. Typical applications include grain drying, chemical drying, baking and curing processes, metal part forming, and all other fresh-air heating applications requiring temperatures below 700°C.

The Linofire series burners are specifically designed by Rapidflame (UK Rapid Flame) for direct combustion heating with fresh air at medium to low temperatures. They are primarily used in industries such as medical, food, and chemical processing, where they facilitate processes like heating, drying, and curing of environments or materials. These burners can also be installed downstream of steam or hot-water preheating sections, enabling even higher heating temperatures. Typical low-temperature applications include HVAC heating for paint-spraying processes, general factory HVAC heating, combination-type air heaters, channel heaters, grain drying, malt drying, and more. Meanwhile, high-temperature process applications encompass air dryers, chemical dryers, fresh-air heating chambers, baking and curing operations, metal component forming, and any scenario requiring fresh air to be heated up to 500°C.

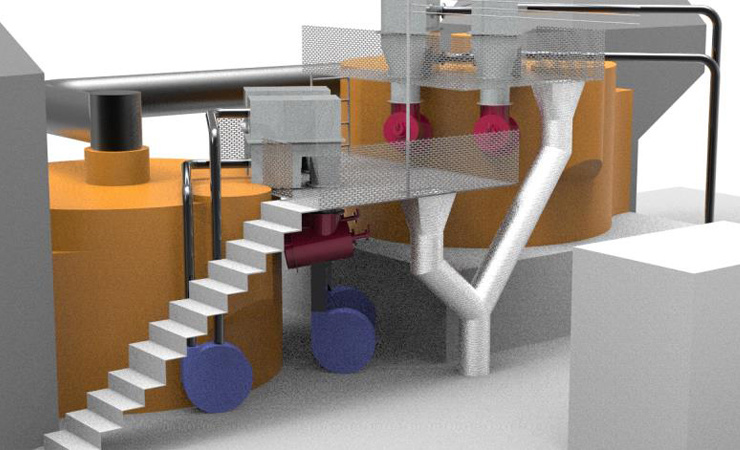

An ideal choice for large dryers, ovens, kilns, thermal fluid heaters, thermal oxidizers, oil heaters, evaporators, boilers, liquid and waste incinerators, and other air heating applications.

Classic Case