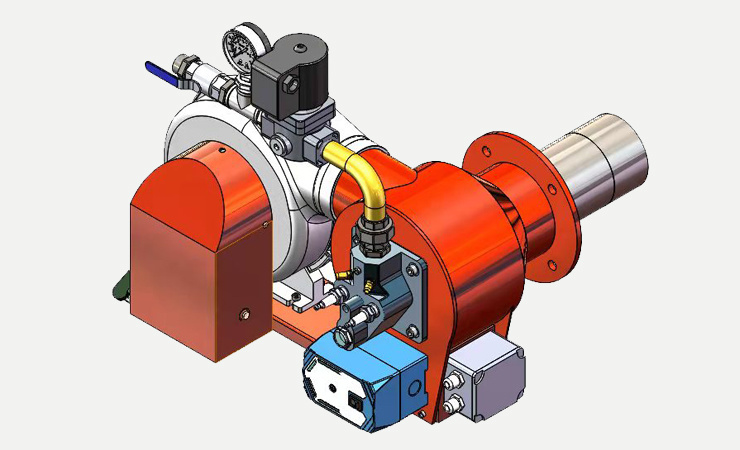

RKL Rotary Kiln Burner

Category:

Diesel combustion engine

Related document download

Helpline:+8618123502747

Office phone:+860757-83370984

Keywords: diesel burner, light diesel burner

undefined

Product Details

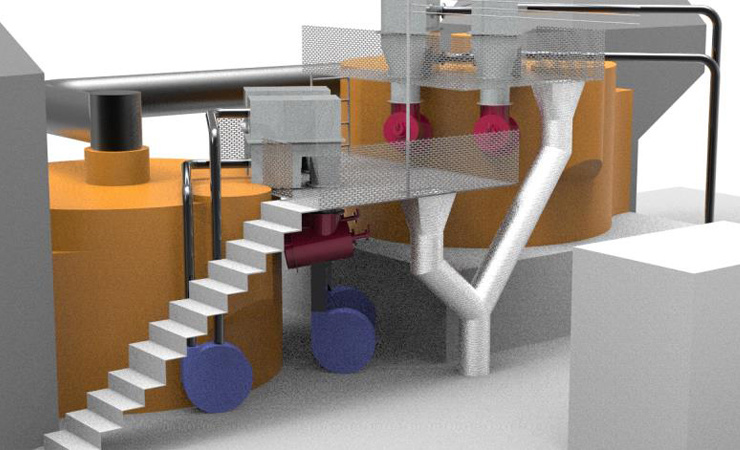

Safety-Production Workshop

Product Description

Product Features

- Design Principle: Each RKL series rotary kiln burner is designed according to the principle of "one kiln type, one design per household."

- Design and Calculation: The head structures of the RKL series rotary kiln burners have all been optimized through CFX simulation, precisely modeling flame length, shape, and temperature distribution maps based on the customer’s kiln type, process parameters, and other specific requirements. This ensures stable combustion, prevents the flame from coming into contact with the kiln lining, and guarantees that the temperature distribution meets the stringent demands of the process.

- Applicable fuels: Suitable for conventional fuels such as light diesel, heavy oil, and coal tar. It can also be used with biofuels, blended oils, waste liquids, and other fuels that contain a certain amount of calorific value. The system supports both single-fuel operation and the use of multiple fuel types.

- Flame Adjustment: Independent manual调节 valves are installed along the clean-air passages of both axial and swirl airflows, and when combined with an adjustable swirl device mechanism, they allow for free and flexible control over the flame's shape and intensity.

- Service Life: The head structure of the RKG series rotary kiln burners has undergone high-temperature and wear-resistant treatments, effectively extending the equipment's service life.

- Installation method: The RKL series rotary kiln burners are mounted on a mobile carriage, which can be configured either with ground rails or a suspended system as needed. In addition to moving the equipment, the mobile carriage also allows for precise adjustment of the nozzle positions on the RKL series rotary kiln burners, ensuring optimal performance even under complex kiln conditions.

- Environmental Emissions: Fuel is atomized efficiently using a dual-fluid atomizing burner, producing Sauter Mean Diameter (SMD) droplets averaging 50–100 μm. The resulting fan-shaped fuel zone mixes thoroughly with the primary air, ensuring complete blending of fuel and primary air for rapid combustion—thereby reducing NOx and CO emissions. Additionally, the high-momentum design of both the combustion-assisting axial and swirling secondary air streams enables more efficient utilization of secondary air, boosting thermal efficiency while minimizing energy consumption.

Recommended Products

Product Inquiry

* Note: Please ensure you provide accurate information and keep your contact details up to date. We will reach out to you as soon as possible.

Foshan Hongxing Jieneng Technology Co., Ltd.

Company Address: 1st Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province

Helpline:18123502747

Office phone:0757-83370984

Fax: 0757-85653501

E-mail:fshongxing.cn@163.com

Website: http://www.fshongxing.cn

You can also submit your information online, and we’ll get back to you within 24 hours!