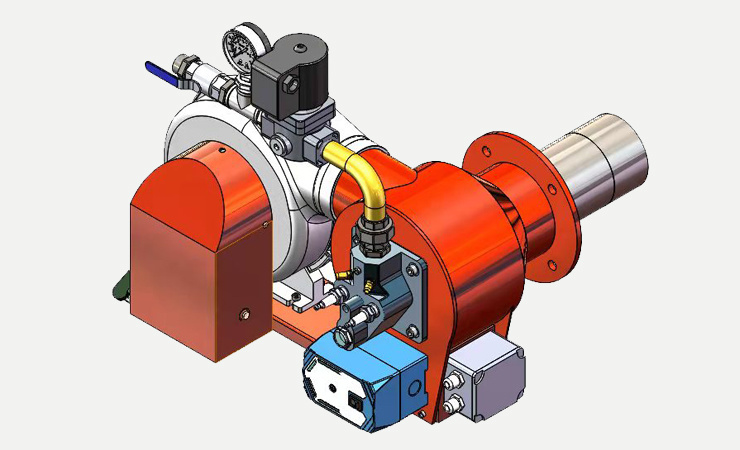

HSA Gas Torch

Category:

Flame-torch gun

Natural gas combustion engine

Liquefied gas combustion machine

Related document download

Helpline:+8618123502747

Office phone:+860757-83370984

Keywords: diesel burner, light diesel burner

undefined

Product Details

• Non-standard products can have their parameter specifications adjusted according to customer needs,

For detailed pricing and other specifics, please contact Ms. He at 18123502747.

• Product Name: Self-preheating gas-energy-saving burner nozzle

Newly built or retrofitted with a self-preheating (regenerative) burner

Heat exchanger recovers waste heat from flue gas, burner nozzle for combustion machine

Baking Machine Ignition Device Combustion System

• Fuel media: Natural gas (NG), Liquefied petroleum gas (LPG)

• Housing material: Aluminum alloy

• Fire tube diameter: Φ65

• Steel pipe lengths: 35 – 50 – 100

• Silicon carbide length: 320

• Silicon carbide export sizes: Φ40 / Φ45 / Φ50

• Installation method: Square 140x140 / Side-wall mounting

• Electrode Type: Single Electrode / Double Electrode

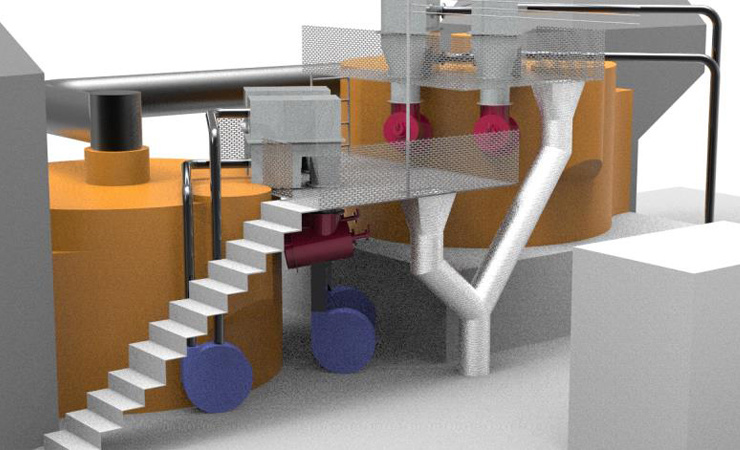

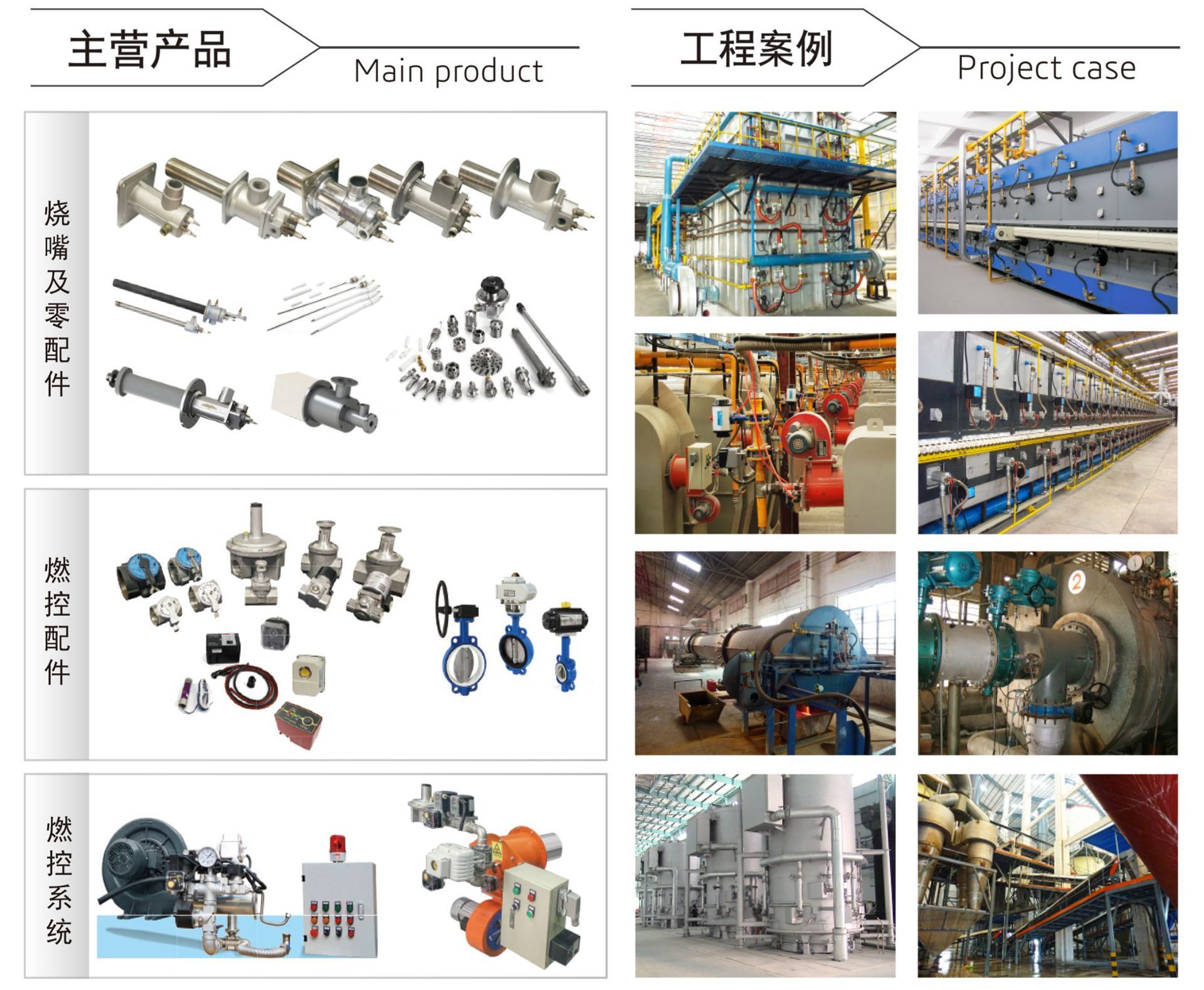

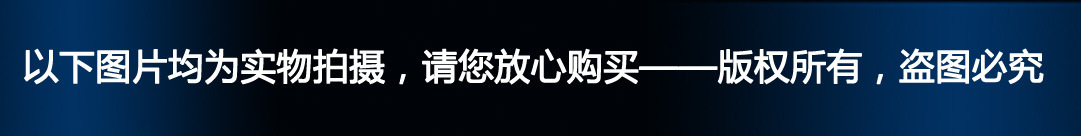

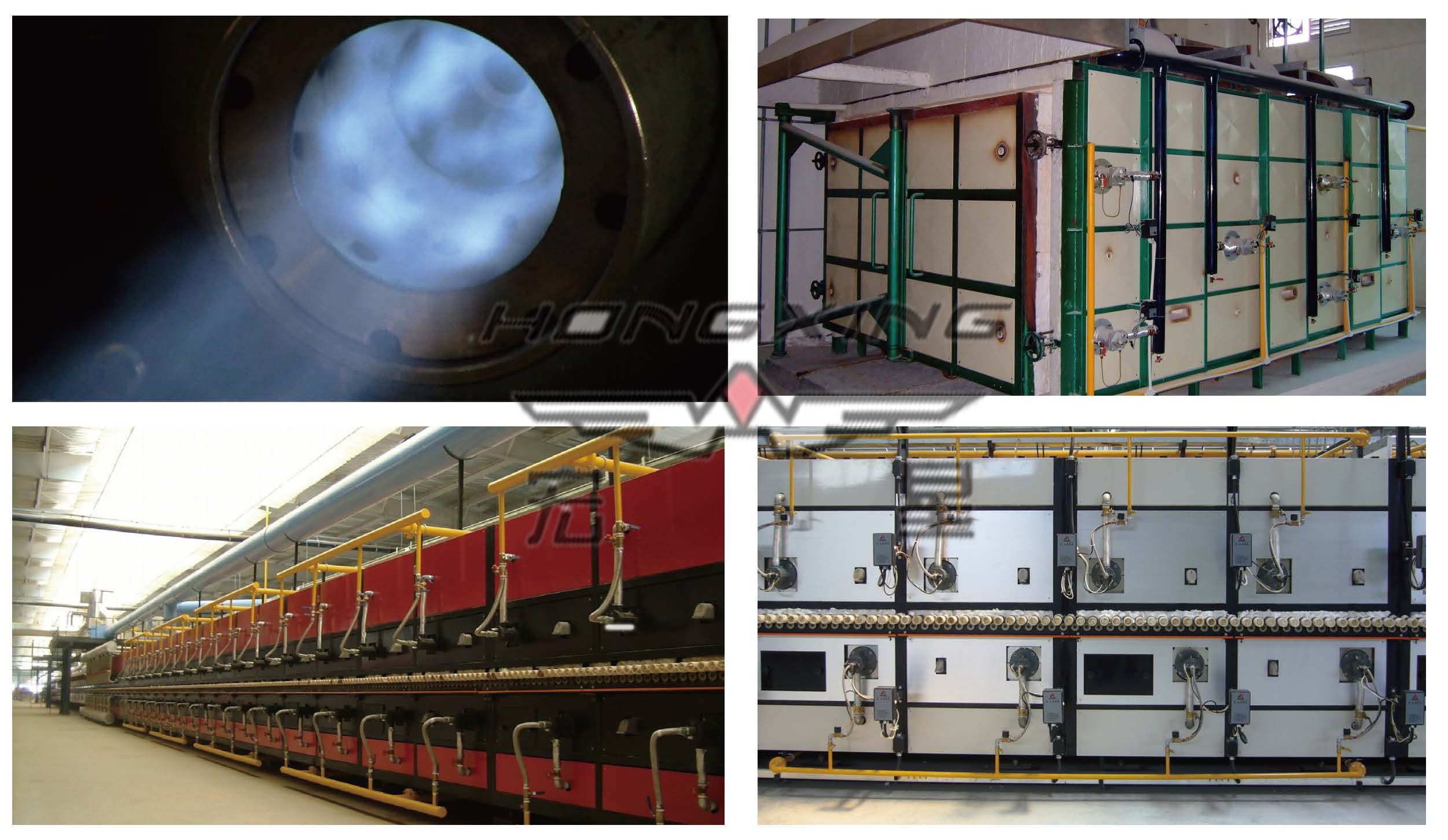

• Typical applications: Gas burners are suitable for heating and heat treatment furnaces that utilize open flames, such as roller hearth furnaces, walk-in furnaces, chamber furnaces, and normalizing furnaces. They can also be used in heat treatment furnaces employing indirect heating with Type I, Type P, and Dual P radiant tubes, including roller hearth furnaces, mesh belt furnaces, silicon steel lines, and galvanizing lines, among others.

Customizable. For more details on product specifications, please contact us.

Please feel free to contact Ms. He!

• Integrated high-efficiency heat exchanger to promptly recover waste heat from flue gases;

• Air preheating temperature can reach up to 650°C (depending on the operating temperature);

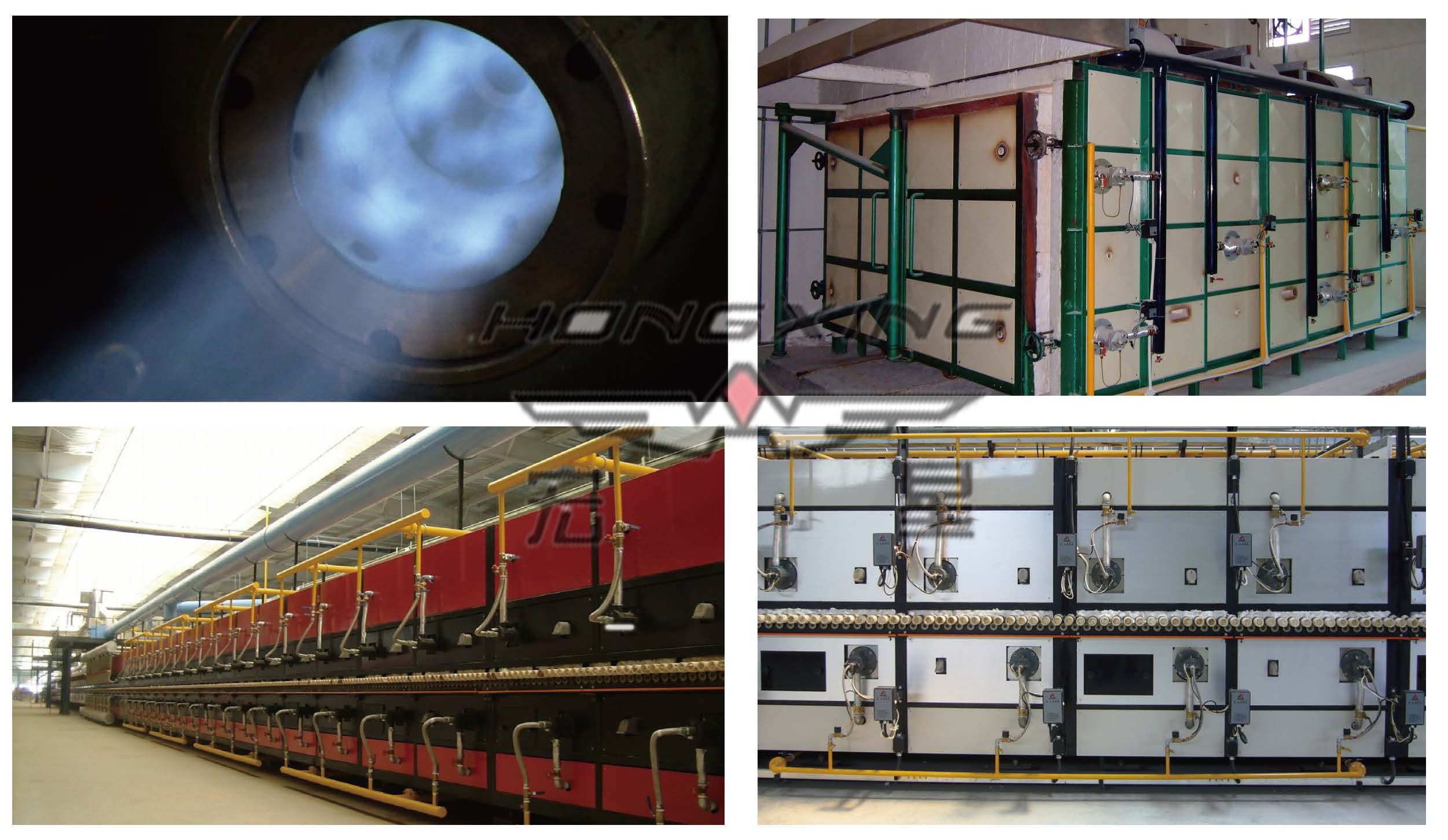

• The flame exits at a high speed, reaching up to 150 m/s;

• Multi-stage air supply efficiently draws in flue gases from inside the furnace, resulting in low NOx emissions;

• Flue gases are 100% exhausted through the burner, eliminating the need for flue ducts inside the furnace;

• Burner receives ambient-temperature air directly; no insulation is required for the air duct.

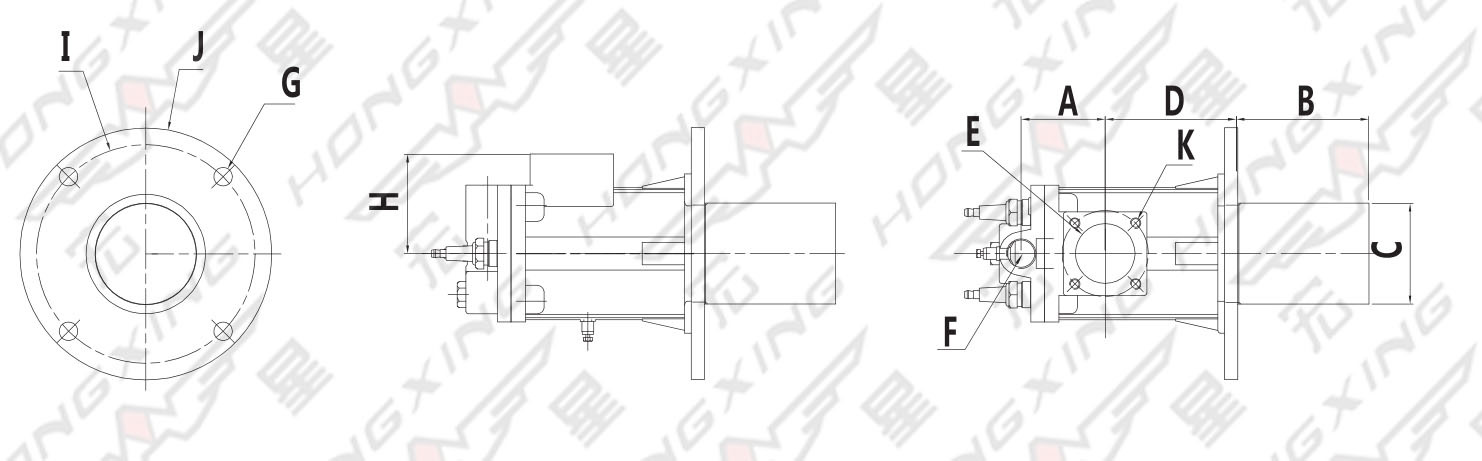

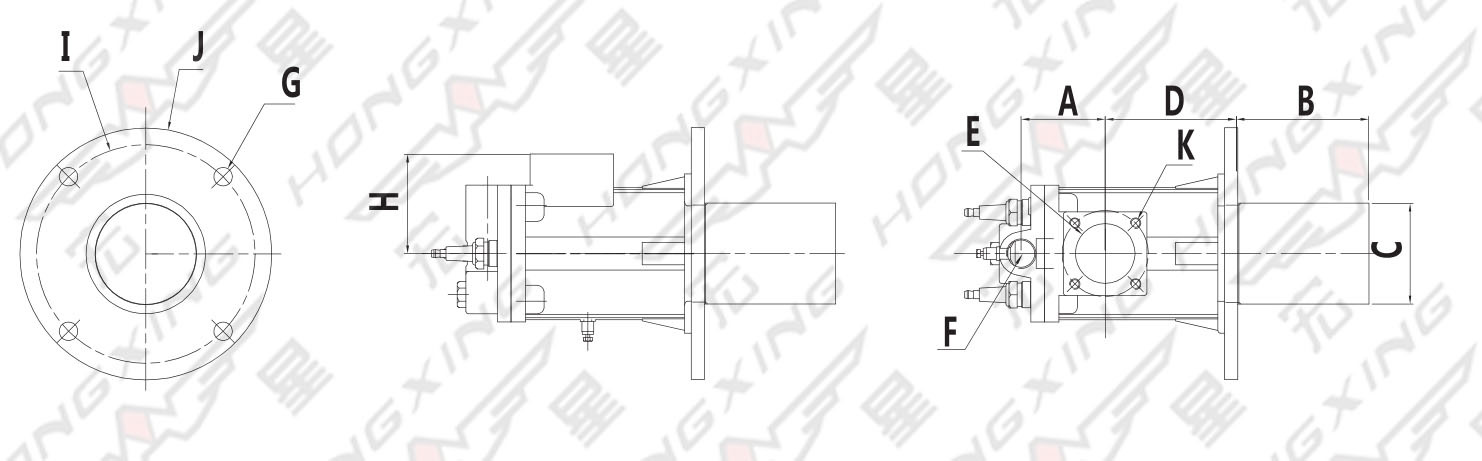

| Model | Maximum Efficiency Kcal |

A |

B |

C |

D |

G |

H |

I |

J |

Gas interface | Air interface |

HSA |

6.5 × 10^4 |

135 |

40 |

Φ65 |

106 |

Φ14 |

85 |

111 |

140 |

G1/2 |

Φ42 |

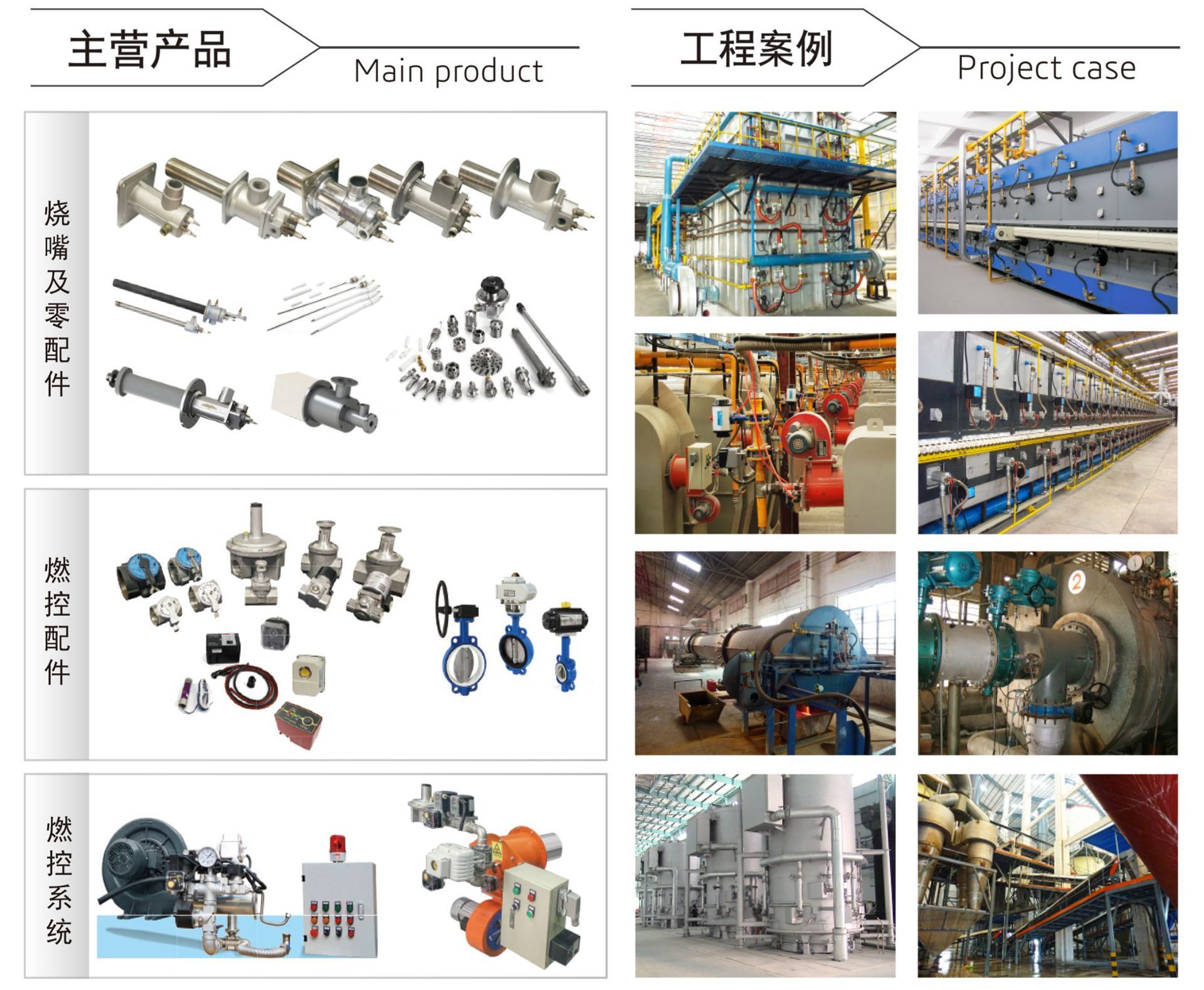

Foshan Hongxing Jieneng Technology Co., Ltd. (formerly Hongxing Thermal Energy Machinery Equipment Co.) is a high-tech company integrating "production, education, and research," specializing in thermal energy combustion equipment, complete sets of automatic combustion control systems for kilns, eco-friendly flue gas treatment devices, metal heat-treatment equipment, and the design of agricultural food film, leather, and coating drying systems. Our company primarily manufactures combustion burners, controllers, combustion control actuators, combustion control valves, and hot-air furnace dryers, among other products. We boast our own dedicated technology development team, along with several senior engineers and professionally qualified technicians. For years, we have been committed to addressing challenges in kiln combustion technology, delivering products that are not only more energy-efficient and stable than comparable offerings, but also earning widespread praise and recognition from industry experts and leading kiln manufacturers alike.

Customer recognition fuels Hongxing's momentum.

Hongxing at the Exhibition Mechanical

: Can

: Can

• Contact: Ms. He

• Phone: 18123502747

• Address: 1st Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province Hongxing's power users endorse Hongxing's power.

Safety-Production Workshop

Product Description

• Non-standard products can have their parameter specifications adjusted according to customer needs,

For detailed pricing and other specifics, please contact Ms. He at 18123502747.

• Product Name: Self-preheating gas-energy-saving burner nozzle

Newly built or retrofitted with a self-preheating (regenerative) burner

Heat exchanger recovers waste heat from flue gas, burner nozzle for combustion machine

Baking Machine Ignition Device Combustion System

• Fuel media: Natural gas (NG), Liquefied petroleum gas (LPG)

• Housing material: Aluminum alloy

• Fire tube diameter: Φ65

• Steel pipe lengths: 35 – 50 – 100

• Silicon carbide length: 320

• Silicon carbide export sizes: Φ40 / Φ45 / Φ50

• Installation method: Square 140x140 / Side-wall mounting

• Electrode Type: Single Electrode / Double Electrode

• Typical applications: Gas burners are suitable for heating and heat treatment furnaces that utilize open flames, such as roller hearth furnaces, walk-in furnaces, chamber furnaces, and normalizing furnaces. They can also be used in heat treatment furnaces employing indirect heating with Type I, Type P, and Dual P radiant tubes, including roller hearth furnaces, mesh belt furnaces, silicon steel lines, and galvanizing lines, among others.

Customizable. For more details on product specifications, please contact us.

Please feel free to contact Ms. He!

• Integrated high-efficiency heat exchanger to promptly recover waste heat from flue gases;

• Air preheating temperature can reach up to 650°C (depending on the operating temperature);

• The flame exits at a high speed, reaching up to 150 m/s;

• Multi-stage air supply efficiently draws in flue gases from inside the furnace, resulting in low NOx emissions;

• Flue gases are 100% exhausted through the burner, eliminating the need for flue ducts inside the furnace;

• Burner receives ambient-temperature air directly; no insulation is required for the air duct.

| Model | Maximum Efficiency Kcal |

A |

B |

C |

D |

G |

H |

I |

J |

Gas interface | Air interface |

HSA |

6.5 × 10^4 |

135 |

40 |

Φ65 |

106 |

Φ14 |

85 |

111 |

140 |

G1/2 |

Φ42 |

Foshan Hongxing Jieneng Technology Co., Ltd. (formerly Hongxing Thermal Energy Machinery Equipment Co.) is a high-tech company integrating "production, education, and research," specializing in thermal energy combustion equipment, complete sets of automatic combustion control systems for kilns, eco-friendly flue gas treatment devices, metal heat-treatment equipment, and the design of agricultural food film, leather, and coating drying systems. Our company primarily manufactures combustion burners, controllers, combustion control actuators, combustion control valves, and hot-air furnace dryers, among other products. We boast our own dedicated technology development team, along with several senior engineers and professionally qualified technicians. For years, we have been committed to addressing challenges in kiln combustion technology, delivering products that are not only more energy-efficient and stable than comparable offerings, but also earning widespread praise and recognition from industry experts and leading kiln manufacturers alike.

Customer recognition fuels Hongxing's momentum.

Hongxing at the Exhibition Mechanical

: Can

: Can

• Contact: Ms. He

• Phone: 18123502747

• Address: 1st Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province Hongxing's power users endorse Hongxing's power.

Recommended Products

Product Inquiry

* Note: Please ensure you provide accurate information and keep your contact details up to date. We will reach out to you as soon as possible.

Foshan Hongxing Jieneng Technology Co., Ltd.

Company Address: 1st Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province

Helpline:18123502747

Office phone:0757-83370984

Fax: 0757-85653501

E-mail:fshongxing.cn@163.com

Website: http://www.fshongxing.cn

You can also submit your information online, and we’ll get back to you within 24 hours!