Frequently Asked Questions

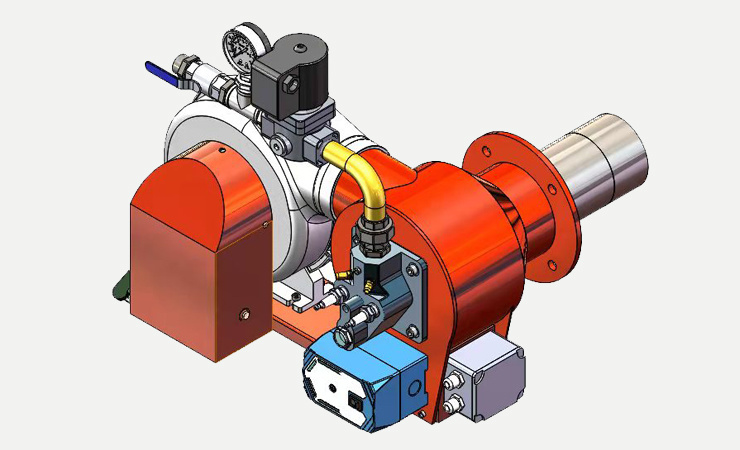

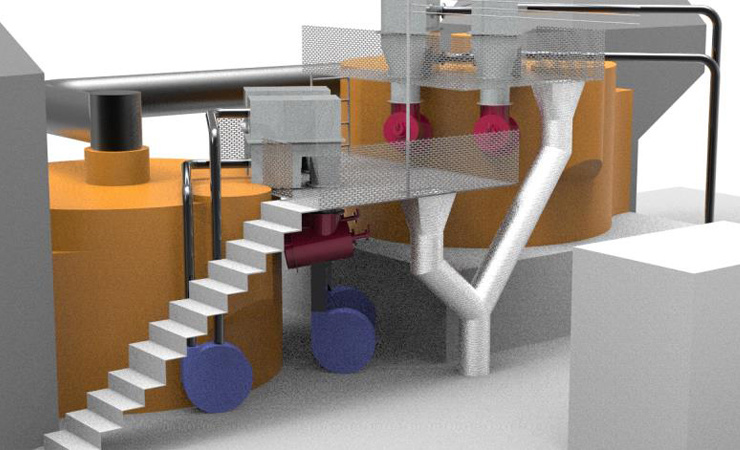

The four key technical highlights—thermal combustion equipment, complete sets of automated combustion control systems for kilns, eco-friendly flue gas treatment devices, and metal heat-treatment equipment—demonstrate how these advanced industrial technologies excel in boosting productivity while ensuring environmental sustainability.

What should you do if thermal combustion equipment exceeds emission standards?

How should the complete set of automatic combustion control equipment for kilns be maintained on a daily basis?

How to troubleshoot and address fault alarms in the complete set of automatic combustion control equipment for kilns?

What causes excessive noise during the operation of thermal combustion equipment?

How can temperature instability in the complete set of automatic combustion control equipment for kilns be addressed?

What should you do if the thermal combustion equipment is difficult to ignite?

Fault phenomenon: No ignition sequence executed after startup

Fault phenomenon: Is the interlock indicator light not on?

Fault phenomenon: Unstable flame

Fault phenomenon: Heating does not meet the requirements.

热能燃烧设备的热效率降低是怎么回事?

Quality vibrates the world; focus leads the future. We give it our all, do our best, serve customers wholeheartedly, and uphold integrity worldwide.

Foshan Hongxing Jieneng Technology Co., Ltd.

Company Address: 1st Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province

Helpline:18123502747

Office phone:0757-83370984

Fax: 0757-85653501

E-mail:fshongxing.cn@163.com

Website: http://www.fshongxing.cn

You can also submit your information online, and we’ll get back to you within 24 hours!