-

About

AboutDeeply cultivating the home furnishing industry for 20 years, willing to be a guardian of the home furnishing industry

-

Product

ProductWe are a high-tech company that integrates "production", "learning", and "research" to provide you with suitable thermal energy solutions. We specialize in thermal energy combustion equipment, complete sets of furnace combustion automatic control equipment, environmentally friendly flue gas treatment equipment, metal heat treatment equipment, and agricultural food film and leather armor spraying and drying design.

-

-

Service Support

Service SupportOur experienced service team quickly understands the actual needs of customers, efficiently designs solutions for enterprises, and manufactures customized high-efficiency, environmentally friendly, and energy-saving combustion equipment.

-

Blog

BlogExperience in the thermal energy machinery industry for the construction and renovation of combustion equipment

-

Contact Us

Contact Us24/7 customer service online, providing consultation, selection, quotation, and emergency problem handling services.

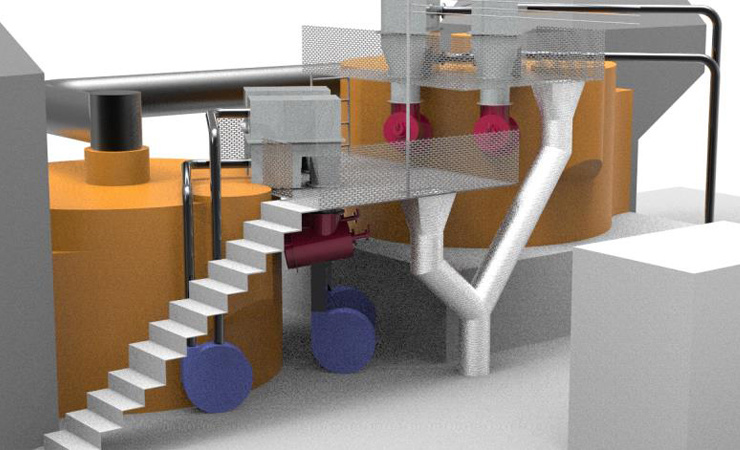

Crematory Solution

Advantages of the Plan

Industrial burners offer solutions that include waste gas incineration treatment and low-emission technologies. By utilizing high-temperature combustion, industrial burners can convert harmful substances in exhaust gases—such as volatile organic compounds—into harmless or less toxic compounds. At the same time, by optimizing combustion processes and fine-tuning fuel-gas mixing ratios, these burners effectively reduce emissions of pollutants like nitrogen oxides and carbon dioxide. This not only significantly cuts down on various pollutant discharges, safeguarding the environment, but also makes waste gas incineration far more efficient, enabling the effective treatment of a wide range of hazardous exhaust gases. Compared to conventional physical or chemical methods of waste gas treatment, industrial burners deliver lower operational costs while providing greater economic benefits.

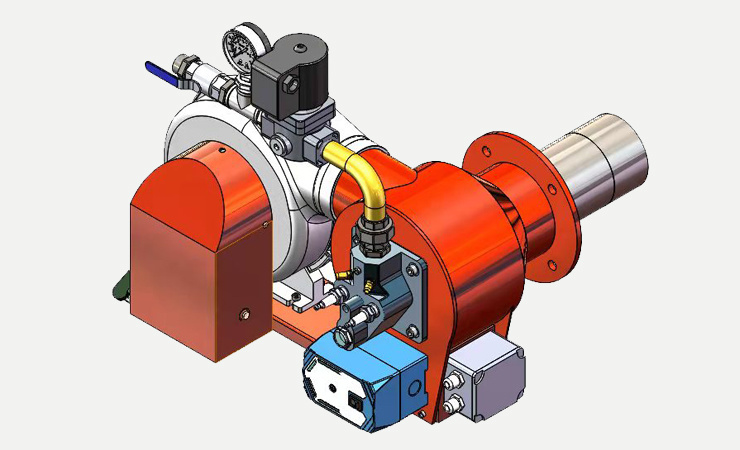

Product Introduction

The RKL series rotary kiln burners are widely used in the metallurgy, building materials, chemical, and solid waste treatment industries.

Classic Case

The fresh air used for desorption is first indirectly heated by exchanging heat with the RTO exhaust gas, then further warmed up via a burner to reach the process-set temperature (around 200°C), before being introduced into the rotor's desorption zone for thermal desorption. The desorbed exhaust gas is typically routed to the RTO for incineration and subsequent emission compliance.

Desorption and Heat Replenishment

Contact Information

Company Address:First Floor, Zhangcha Life Science Park, Chancheng District, Foshan City, Guangdong Province

Helpline:+8618123502747

Office phone:+860757-83370984

Fax:0757-85653501

Email:fshongxing.cn@163.com

Website:http://www.fshongxing.cn