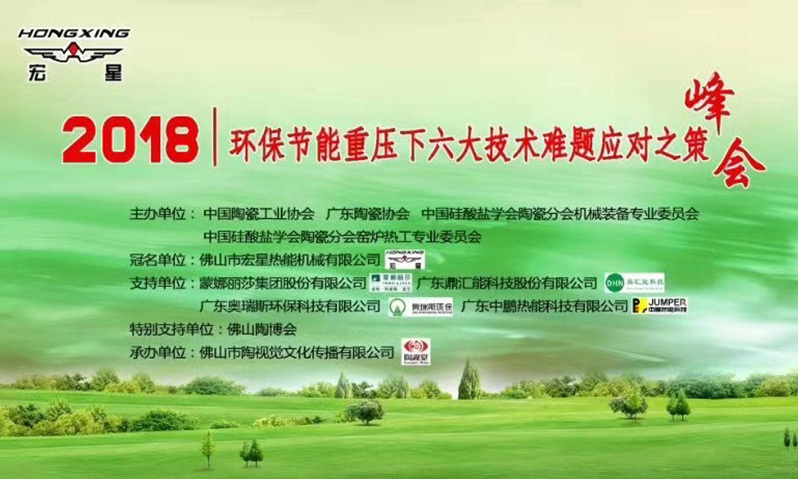

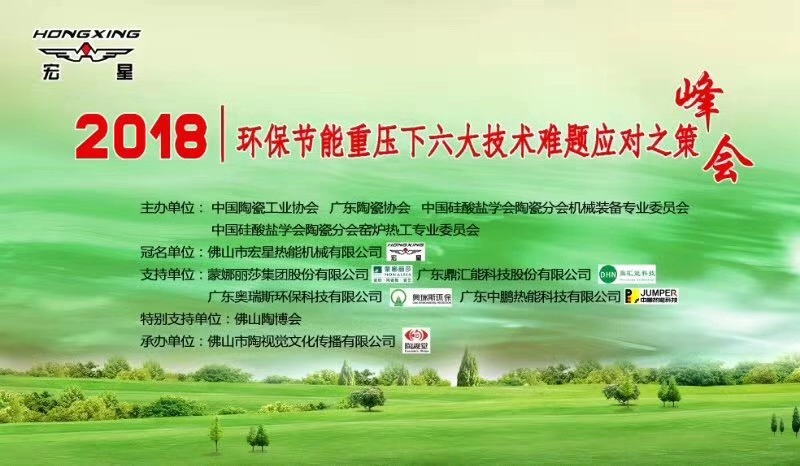

Hongxing Thermal Energy exclusively sponsors the "2018 Summit Forum on Strategies to Tackle Six Major Technical Challenges Amid Environmental Protection and Energy Conservation Pressures"

2024/09/04

In today’s era of increasingly stringent environmental pressures and energy-saving demands, where should the ceramic industry go from here? How should ceramic factories respond to these challenges? And what kind of energy-efficient solutions and eco-friendly equipment can help the industry overcome its current difficulties together? On October 20, 2018, a grand summit forum themed "Strategies for Tackling Six Major Technical Challenges Under Intense Environmental and Energy-Saving Pressures" was held with great success in the conference room on the fifth floor of China Ceramic City!

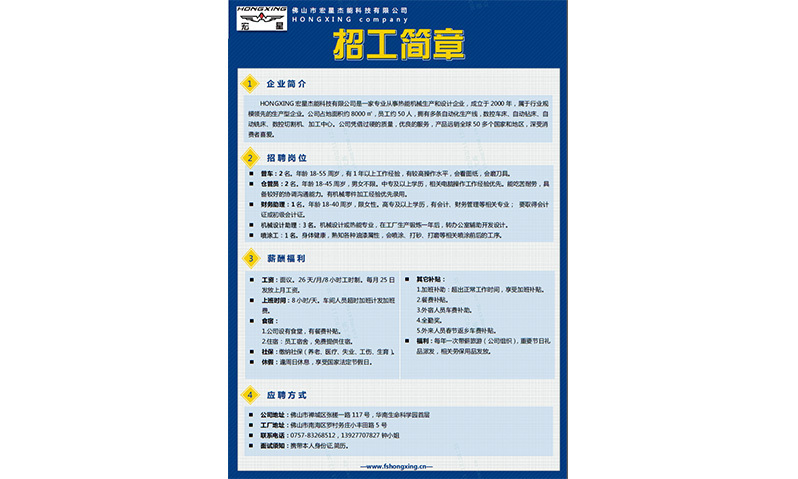

This forum is proudly sponsored throughout by Foshan Hongxing Thermal Energy Machinery Co., Ltd.! Organized by the Guangdong Ceramic Association, the Mechanical Equipment Professional Committee of the Ceramics Division of the Chinese Society of Silicates, the Kiln & Thermal Engineering Professional Committee of the Ceramics Division of the Chinese Society of Silicates, and the Foshan Ceramic Association; it receives strong support from Mona Lisa Group Co., Ltd., Guangdong Dinghui Energy Technology Co., Ltd., Guangdong Aores Environmental Protection Technology Co., Ltd., and Guangdong Zhongpeng Thermal Energy Technology Co., Ltd., while also benefiting from the generous assistance of the Foshan Ceramic Expo and the dedicated sponsorship of Foshan Tao Vision Cultural Communication Co., Ltd.

Over 70 representatives from leading enterprises, along with numerous media personnel—totaling more than 100 participants—attended this forum. Among them were Chen Huan, Vice President of the China Ceramic Industry Association and Chairman of the Guangdong Ceramic Association; Feng Bin, Chairman of the Foshan Diamond Enterprise Group Co., Ltd. and Director of the Foshan Ceramic Society; Zhang Baiqing, Vice Chairman of the Ceramics Branch of the China Silicate Society and Director of the Mechanical Equipment Professional Committee, as well as a professor at Jingdezhen Ceramic University; Zeng Lingke, Vice Chairman of the Ceramics Branch of the China Silicate Society and Director of the Kiln Thermal Engineering Professional Committee, also a professor at South China University of Technology; Huang Xiangtao, Chairman and Secretary-General of the Ceramic Manufacturing Committee of the China Building Materials Circulation Association; Li Mingyu, Professor at Jinan University; Li Jiaduo, Deputy Secretary-General of the Foshan Ceramic Society; Xie Binghao, Engineer at the Foshan Energy-Saving Technology Service Center; Zhang Chengwei, Director of the Brand Planning Department at Foshan China Ceramic City Group Co., Ltd.; Wang Zhen, Assistant General Manager of the Energy Conservation Services Division at Southern Power Grid Integrated Energy Co., Ltd.; Feng Fa, Manager of the Energy Conservation Services Division at Southern Power Grid Integrated Energy Co., Ltd.; Luo Hangguo, General Manager of Foshan Hongxing Thermal Energy Machinery Co., Ltd.; Zhang Qikang, Director of Mona Lisa Group Co., Ltd.; Luo Jienan, Engineer at Foshan Hongxing Thermal Energy Machinery Co., Ltd.; Zhao Zuxi, General Manager of Guangdong Dinghuineng Technology Co., Ltd.; Liu Yanfeng, General Manager of Guangdong Aoruis Environmental Protection Technology Co., Ltd.; Fang Changjin, Deputy Director of the Marketing Center at Guangdong Zhongpeng Thermal Energy Technology Co., Ltd.; Cheng Zhaohua, General Manager of Foshan Jia Yun Kiln Technology Co., Ltd.; Li Ping, Associate Researcher at the Guangzhou Institute of Energy, Chinese Academy of Sciences; Zhang Guihua, Assistant to the Chairman of Guangdong Zhongyao Kiln Industry Co., Ltd.; Pan Xiong, Director of Foshan Jianjie Ceramic Materials Technology Co., Ltd.; Huang Yi, Technical Director of Foshan Saiindi Environmental Protection Technology Co., Ltd.; Tian Yong, Production Plant Manager of Guangdong Xinyipai Co., Ltd.; Chen Xuanyao, Production Plant Manager of Guangdong Guanxing Ceramic Enterprise Co., Ltd.; Cai Duoxin, Production Manager of Guangdong Guanxing Ceramic Enterprise Co., Ltd.; Zhuang Shichao, Engineer at Foshan Jinjiufang Ceramic Co., Ltd.; Xian Jiaxian, Production Center Manager of Guangdong Xin Yipai Co., Ltd.; Nie Weinan, Environmental Protection Director of Guangdong Xin Yipai Co., Ltd.; Huang Guohua, Production Manager of Guangdong Xinmingzhu Ceramic Group Co., Ltd.; Tao Zhihang, Production Manager of Guangdong Samit Ceramic Co., Ltd.; and Qiao Fudong, Market Director of the Marketing Department at Foshan Ceramic Research Institute Co., Ltd., as well as a director and consultant at Foshan Taovision Cultural Communication Co., Ltd.—among other distinguished guests.

Due to the attendance exceeding expectations, two additional rows of stools were hastily set up in the 100-person conference room on the fifth floor of China Ceramic City—yet even these couldn’t fully meet everyone’s seating needs. Undeterred, the late-arriving participants stood quietly in the corners, patiently listening to the entire session! We were deeply moved by their insatiable thirst for knowledge and truly grateful for their enthusiastic support. All attendees demonstrated a strong sense of professional mission and social responsibility. It is precisely because of this dedicated group of individuals that the ceramic industry continues to radiate its boundless charm and vitality.

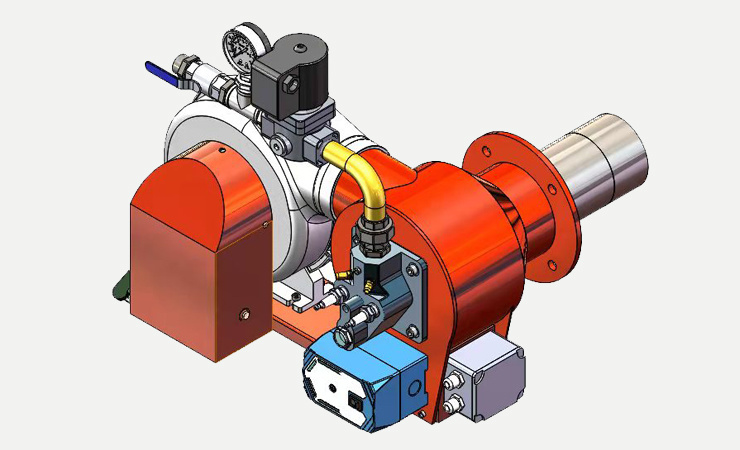

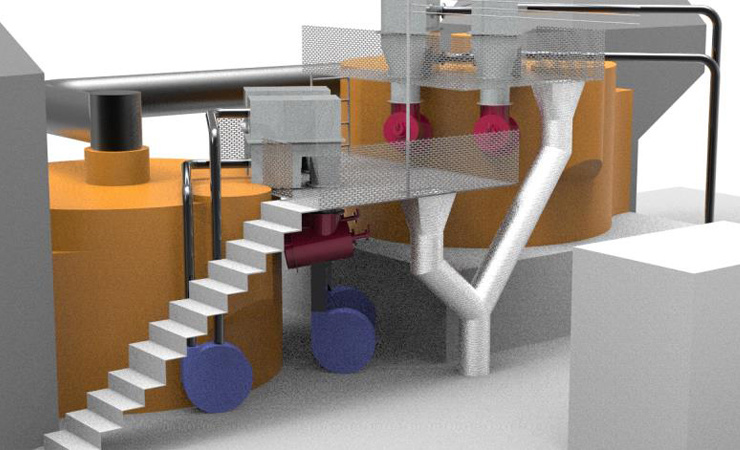

Mr. Roger Nan from Hongxing Machinery Factory separately discussed the configurations and usage effects of combustion systems applied in spray towers—specifically, the producer gas burners for spray towers, burners used in drying kilns, pipeline-type burners for preheating and heat recovery, and burners designed for roller hearth kilns—including their respective nozzles. He also demonstrated via video a comparison of flame characteristics when these burners are operated using either coal gas or natural gas.

Finally, Engineer Luo also provided a comprehensive analysis of common issues in coal-to-natural-gas conversions, including carbon buildup, improper equipment selection, tempering, and failure to adjust kiln parameters. With 20 years of combustion design experience, coupled with meticulous data and richly illustrated explanations, Hongxing’s advanced and well-reasoned combustion and energy-saving technology—boasting exceptional energy efficiency and environmental benefits—left everyone thoroughly impressed!

From a systematic and comparative perspective, let’s take a scientific look at the issue of kiln energy efficiency—where exactly lies the limit of energy conservation and emission reduction? At the forum, Fang Changjin, Deputy Director of the Marketing Center at Guangdong Zhongpeng Thermal Energy Technology Co., Ltd., introduced Zhongpeng Kiln’s three innovative systems: structural innovation, functional innovation, and management system innovation. He then shared his unique insights on how to go further down the path of energy saving and emission reduction—covering aspects such as ductwork design, refractory material structure optimization, combustion systems, intelligent monitoring systems, along with ceramic enterprises’ process formulations and raw material choices.

The path to environmental protection and energy conservation is long and challenging, but as members of the ceramics industry, we will bravely face difficulties and move forward with determination!

Other news

2024-09-04