Environmental Protection Industry

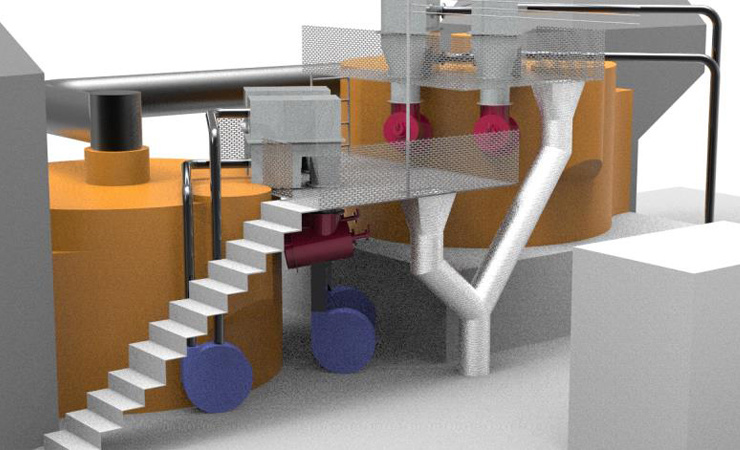

Traditionally, domestic liquid-tank heating methods have relied on steam or high-temperature water for heat exchange during processes such as pre-cleaning, phosphating, and degreasing. This approach necessitates the installation of complex heating equipment, extensive piping networks, valves, and heat exchangers both inside and outside the factory, around the liquid tanks. Not only does this consume valuable space within the facility, but it also increases maintenance costs. Moreover, heat transfer efficiency tends to be low when using high-temperature water or steam, leading to higher operational expenses.

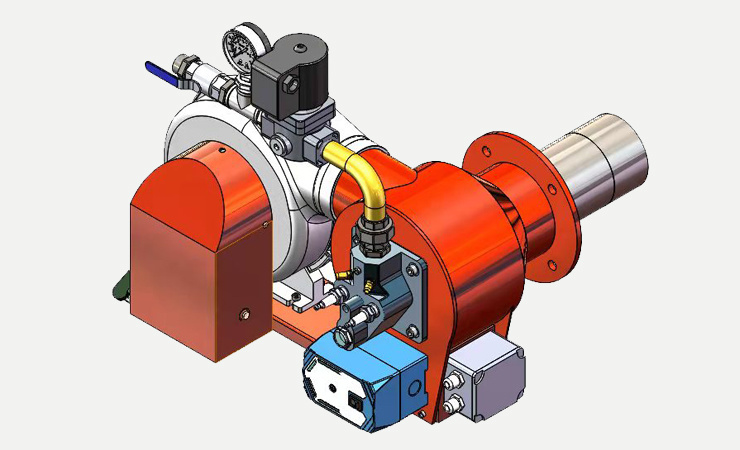

Using gases such as natural gas, propane, and butane as fuel, the flame burns directly within the heating tubes at the bottom of the liquid tank, efficiently and uniformly heating the liquid inside through the optimized length and arrangement of the heating tubes. This system achieves a thermal efficiency of over 80% and enables automatic temperature control, making it the ideal choice and the future direction for industrial liquid-tank heating applications.