A Review of Indonesia's Biomass Co-firing Practices in Coal-Fired Power Plants

2025/04/21

1. Policy Framework and Implementation Pathways 1. National Goals and Mandatory Policies

-

Policy Instruments : Through

Renewable Energy Certificate (REC) Mechanism and electricity price subsidies incentivize enterprises to participate, but price caps on biomass (not higher than subsidized coal prices) cause conflicts in the raw material supply chain.

-

Standard Setting The government is formulating national standards for biomass pellet power generation (SNI) to regulate fuel quality and market access.

2. Economic and Emission Reduction Balance

2. Technical Details and Achievements of Demonstration Projects 1. PLN Indonesia Power National Pilot Network

-

Technical Breakthroughs :

- 100% Biomass Pilot : West Kalimantan

Sintang Power Plant In 2023

Achieved 15 days of pure biomass operation , setting the longest record in Indonesia.

-

Technical Pathway Using palm shell co-firing (replacing 50% coal), utilizing its 3281 kcal/kg calorific value (comparable to low-calorie coal), cumulatively producing 620,000 kWh of green electricity and reducing emissions by 600–800 tons CO2e.

- Bukit Asam Power Plant (commissioned in 1989) Coal powder boiler technology limitations only allow co-firing of powdered biomass (e.g., sawdust), resulting in low raw material utilization and failure to meet government targets.

3. Technological Innovation and Raw Material Management 1. Pyrolysis Technology Optimizes Fuel Characteristics

-

Community Cooperation Model PLN promotes biomass crop planting (such as fast-growing forests) on vacant land around power plants, forming a

"Fuel-Feed" Circular Economy that drives employment and income growth.

4. Existing Challenges and Policy Recommendations 1. Core Issues

-

Price Mechanism Conflicts Government price caps cause

biomass suppliers to have thin profits which in turn affects

the stability of the supply chain. 。

-

Differentiated Subsidies Increase subsidies for power plants using local waste

to reduce import dependence. ,

降低进口依赖。

5. Summary

Indonesia, through

mandatory policy drives and

technological innovation pilots has successfully built a biomass co-firing system in coal-fired power plants. For example, Sulawesi Mining Investment Co., Ltd. (SMI) power plant uses palm shells for coal co-firing power generation, cumulatively producing 620,000 kWh of green electricity and estimating emission reductions of 600 to 800 tons of CO2 equivalent. This shows that biomass co-firing in coal-fired power plants in Indonesia not only helps reduce greenhouse gas emissions but also

enhances the synergy between power generation efficiency and community economy. However, it is necessary to overcome

the raw material-technology-policy coordination bottleneck and learn from the local waste survey experience of countries like China to optimize the supply chain and refine standards, in order to achieve

the leap from "pilot demonstration" to "large-scale application." 。

United Youfa focuses on carbon neutrality services, carbon asset management, and zero-carbon thermal energy services, with the mission to provide biomass zero-carbon solutions and promote the construction of a zero-carbon society. The company's carbon neutrality business started in 2005, and for nearly 20 years it has provided multiple energy and dual-carbon field services to thousands of domestic and international clients/institutions, managing carbon assets exceeding 50 million tons, with a highly experienced team!!

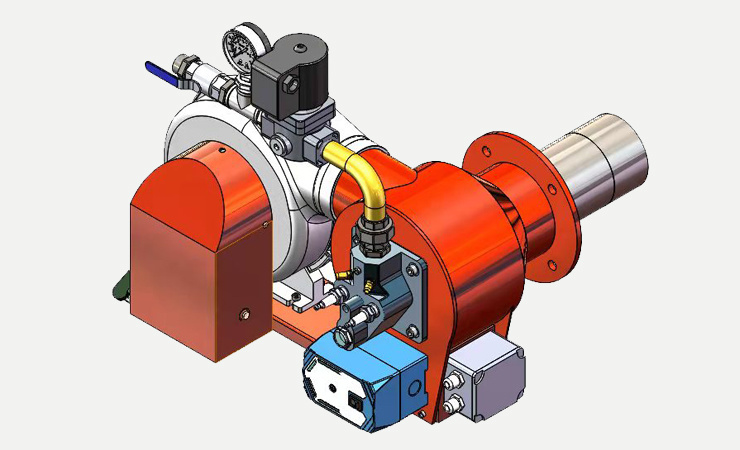

Burner

Previous page

Other news

2024-09-04